Protection that workers will love to wear.

Let’s be frank.

Reducing the risk of heat stress, is not just a matter of safety, but also of worker compliance. When the risk of heat stress is too high, workers will cheat and wear garments non-compliantly or may not wear them at all.

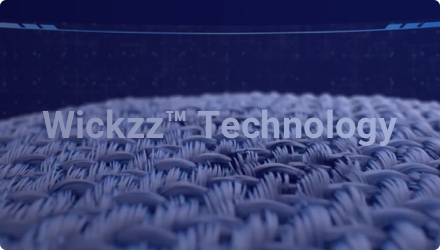

When it comes to the battle against heat stress and AR/FR PPE, there are four main pillars to remember – lightweight, breathable, moisture wicking, and minimal dry time. At GlenGuard, we look at how these elements work together to form a performance fabric for the battle against heat stress.

GlenGuard AR/FR

GlenGuard AR/FR

Scroll right to explore

Scroll right to explore

Custom colors available upon request.

Custom colors available upon request.